- Description

-

Details

Would you like to build the smoothest Triumph twin possible? Then, you'll need to start with the 76-degree M.A.P. Crankshaft.

Triumph twins have always been known for vibrating. That's because both pistons rise and fall at the same time on the standard 360-degree crankshaft making it difficult to balance without compromise. The 180-degree crank should be inherently smoother, but in a parallel Triumph twin, it suffers from vibration due to the increased rocking couple, which is best described as plane imbalances on the Y or Z axis of the crank (basically twisting at the ends). Cranks use counter weights and varying balance factors to lessen these vibrations, however there are limits to what they can do. The 76-degree crankshaft concept came from the well-known engineer Phillip Irving whose idea was to offset the journals of the crank (for a vertical twin) so that as one piston is stopped at top dead center, the second is at its maximum velocity. For an engine with 82mm stroke and a 6.5" long rod the calculation works out to be 76 degrees. There has been some chatter that a better offset would improve the harmonics but in reality, increasing the offset adds to that ugly "felt" vibration from the added rocking couple. We feel that Irving knew of this compromise and considered it when proposing his view. it is only a compromise if it doesn't work as intended. Back-to-back tests in Australia and New Zealand (love those boys downunder) have verified the conclusion, ie The 76 degree offset concept, in a Triumph big twin, offers the smoothest possible crankshaft motion eliminating most of the harsh and unwanted vibration, has increased the revability (more midrange acceleration) with a delightfully different sound of possibly a Ducati on the pipe- simply the best combination to keep these bike on the road wanting to be ridden - wonderful

Fits:

- All Triumph 650-750cc Twins built after June 1971 (GE27209) though 1983 with metric timing side main bearing. Can be adapted to earlier 650cc twins by purchasing a "conversion" bearing (metric ID with inch dimension OD) available at M.A.P. Cycle (see below)

Specifications:

- 82mm stroke

- 1-5/8" journal (use with any replacement OEM Triumph 650/750 twin rod shells (B2026M))

- Crank Journal Offset (76 degrees)

- Long snout for better alternator rotor support

- Approximately 18 pounds

- Dynamically balance with a pair of 604gram bob weights creating roughly a 49-51% balance factor dependent of remaining components

Features:

- EN40B Billet Material - EN40B steel

- Rated 123,000-144,000 psi

- The Best alloy used for cranks in British Motorcycle engines

- "Tear-drop" journal oil holes for better big-end oiling

- Heat treated

- "Ion Nitrite" treatment for longest life (similar to British Tuftriding)

- Ionized nitrogen is vacuum deposited onto the crank surface in an oven, penetrating .010 to .012 inch into the metal surface and changing the microstructure of the steel, surface hardness is doubled from 30 to 60 on the Rockwell scale, while fatigue life is increased by 25 percent.

- Shot peened to reduce internal stresses

- Generous Crank "Fillets" for strength and rigidity

- Out-bounded Counterweight to lessen the possibility of crank flex

Note:

- Highly recommend the use of MAP7061 Forged Steel rods (4340 ultra light forged steel)

- The 76-degree crankshaft can be used on pre-1971 models, but it requires the use of a "conversion" timing side main bearing (70-3835/MI (ball bearing) or 60-7362/MI (latest factory located roller) or the crank journal can easily be turned to fit imperial unit (inch) bearings.

- This must be used in conjunction with a 76 degree electronic ignition, and 76 degree camshafts (stocked at M.A.P. Cycle)

About crankshaft bob weight:

- Bob weight is the amount of weight added to each journal before it is spun also known as dynamically balanced. It is calculated in the following manner:

Bob weight = (complete piston assembly + small-end rod weight) X (balance factor) + (big-end rod weight + bearing shells)

Additional Information

SKU MAP9215/EN-76 - Additional Information

-

Additional Information

SKU MAP9215/EN-76 - Reviews

-

Write Your Own Review

- Product Question

-

Product Questions

No questions yet. Be the first to ask the question! - Shipping Estimation

-

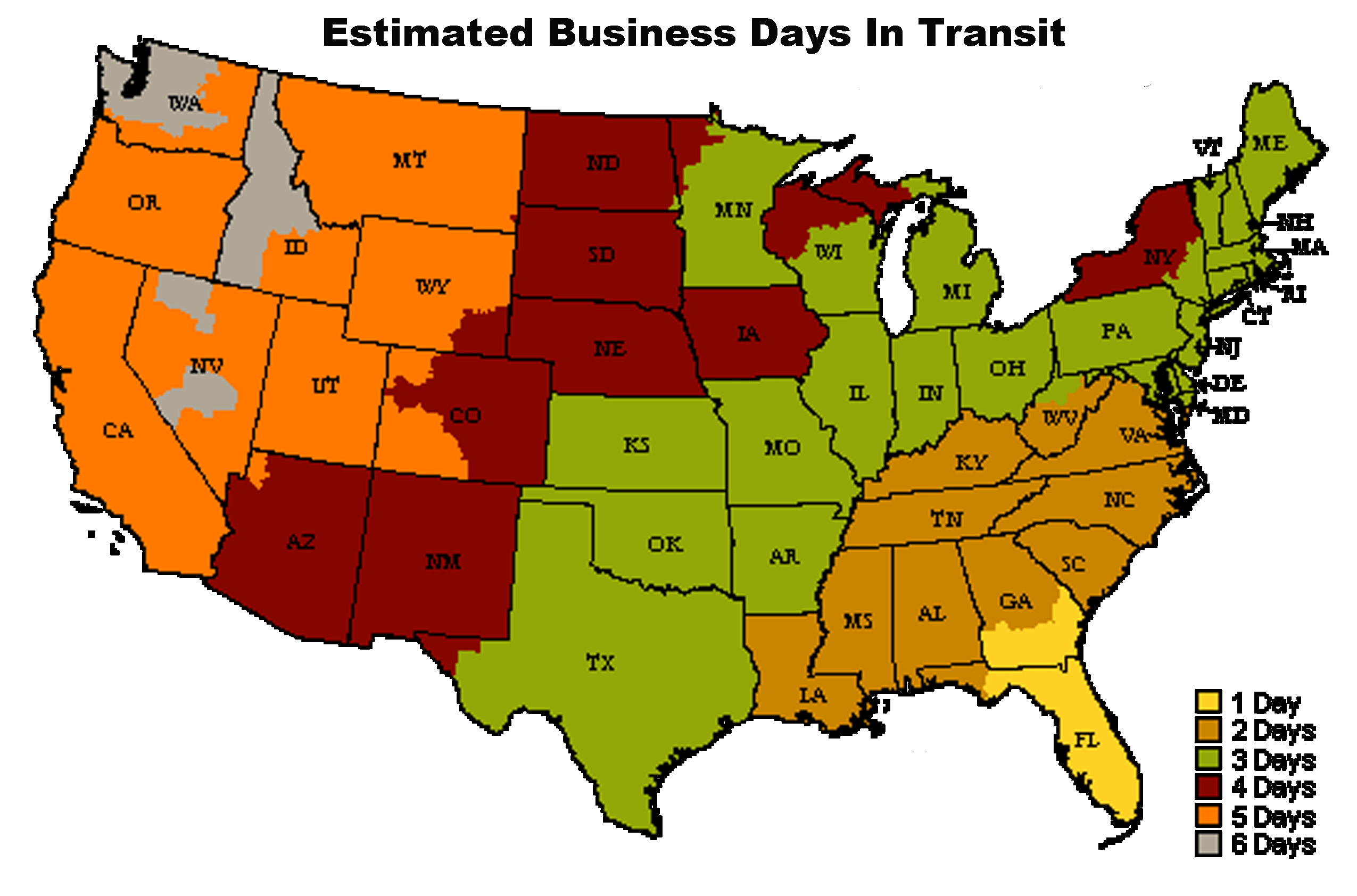

You can use this section to calculate shipping costs on all available methods for the item on this page, or your entire shopping cart.

-

-

-

-

Yes No

-

General : 727.381.1151 Toll Free : 1.800.875.BRIT(2748)

Menu Search Account

Cart

0

Cart

0

My Cart

Recently added item(s) ×

You have no items in your shopping cart.

Loading Methods & Rates

Loading Methods & Rates

Loading...

Loading...